Custom Stain Program for Prefinished Wood Stair Parts

Stair-treads.com is the only manufacturer that offers custom stained prefinished stair treads in job-lot quantities. With our custom stain program, you no longer need to settle for "close enough." You can have truly custom stained stair treads made with the same service you would expect from an on-site installation crew; the quality of our stock stain colors; and the durability of our Aluminum Oxide finish.

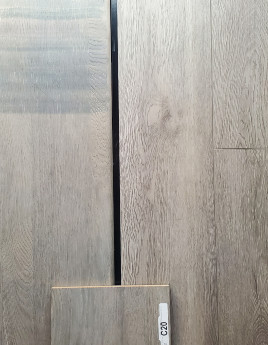

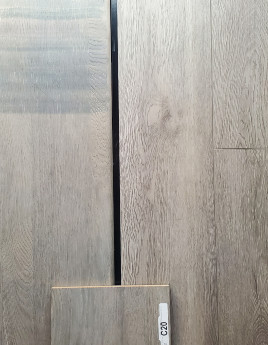

Custom stain blending in progress

Custom-stained stair treads offer several advantages:

- Get the Aluminum Oxide protection of our Diamond Coat II over the stain color of your choice

- Allow your contractor or painter to focus on the larger part of your project instead of spending days tinkering with wood stains

- You can now have almost any stain color applied to your wood stair treads without browsing through dozens of color samples

- You can often find discounted or closeout specials on hardwood flooring and have your stairs coordinated to the floor

- Shade variations of flooring can be accommodated by custom blending to the flooring color

Making stain is a complicated and time-consuming process but, luckily our production personnel are very skilled in blending stain colors. Even with their skill and experience, it can often take several full days of many trial-and-error attempts before a good blend can be achieved. On some of the more difficult colors, it is common for more than a week to be spent adjusting the stain formulas to achieve a good look. Because of the extra time and labor involved, there is a set-up charge applied to custom blended colors, but the extra cost is nothing compared to the time you and your contractor will save by having pre-stained custom-stained stair treads and stair components. The set-up charge applies only once per color and covers any and all prefinished products ordered for a period of 90 days after we complete your order - for example, if you need custom-stained and prefinished newel posts, risers, treads, handrail, and moulding, there is only be a one-time set-up charge which covers all the different products and, should you need to order additional parts in the same color later, there are not additional set-up charges for 90 days!

Our custom stain program is a two-step process:

- Initial sampling and take-off

- Production run

Staining wood products to a unique or special color in a production environment requires a very specialized program and you'll work closely with a member of our sales staff throughout the entire process. To begin the initial sample take-off process, you will need to contact us with the details of your project. We'll gather as much detail about your particular project as possible and assist in placing the initial order for your custom sample (we may be able to provide a rough initial quote based on the details you provide but, more often than not, we need to actually see the flooring to provide an accurate quotation). After placing the initial sample order, we'll send a Sample Authorization Form to you via e-mail.

Once you receive the form, mail it along with several pieces of your flooring to us and we'll take it from there! Remember, we need several 8”-12” (at least 1 square foot) samples of the flooring you would like to have coordinated (the more pieces you send us the easier it is for us to coordinate your color - it's impossible to achieve an accurate blend from 1" wood scraps and nearly impossible to see the color range of your flooring from only 1 board).

After we receive your samples, our in-house stain experts will formulate a stain color and send you a 13" sample swatch of finished wood for your approval. This process typically takes approximately several weeks to a month. Once we have formulated the color, we will send this custom finished piece back to you to approve. On the back of the sample, there will be a sticker with a stain approval number (Form ID). This form ID links your color to a stain process we store in our computer system and wood library for quick reference at a later date. To approve the custom stain, simply sign the bottom of the label and send us a picture with the form ID number.

The custom set-up charge is $500 per color and is non-refundable. This set-up charge helps cover a portion of the set-up time and materials required to make the take-off of your color. For us to begin creating the stain color, you will need to contact your sales rep and place the initial sample order. Once you receive the initial sample swatch, you can approve it if you are satisfied with the color, or tell us of any changes and we will reformulate and re-sample the color for you at no additional cost (we may need to see pictures of the sample next to your flooring for a better idea of the color-tweaks needed or we may need additional samples from you). We employ some of the most skilled team members in the industry and we’ll strive to create a product that coordinates well with your flooring samples. Remember, we work worth real, solid wood, so the final product will not be an exact match to manufactured products such as laminate or LVT, but we have a vast arsenal of tools and techniques at our disposal to bring you the best looking and highest performing product on the market.

Throughout the process, you'll be working with a dedicated member of our sales staff who is available to assist you from sample to staircase.

We take the time, so you don't have to.

Custom blended stains for Stair Treads

So how do I get started?

Contact a member of our expert staff and they will help you place your initial order, ensure that you receive all the necessary forms, and can also provide an overview of the overall cost of your custom stain project.

Please Note: Special order policies apply to custom stained products. Please read and be familiar with these policies prior to placing any order.

Log In